Brief introduction of semi-trailer brake system design and trouble shooting(oen)

With the rapid development of highway transportation, Semitrailer tractor with high load-bearing, economic, efficiency and other characteristics of the industry attention, has gradually become the main model of long-distance logistics. Many first-time semi-trailer contact drivers, semi-trailer structure and design, maintenance of the lack of understanding, in driving because of brake system failure often helpless, or even lead to serious accidents. As the saying goes, “A journey of a thousand miles begins with a single step”, it is necessary for us to study and understand the vehicles we drive

Semi-trailer brake system to meet the basic requirements

The brake system design of the semi-trailer has the mandatory rigid requirements, because the tractor semi-trailer has the special articulation characteristic, in satisfies the vehicle deceleration, the parking function and so on basic conditions, also to meet the following requirements:

1, trailer and tractor brake system between the relationship between the braking role of mutual cooperation.

2. The coordination of braking system between trailer and tractor. The order of braking action is tractor front wheel, semi-trailer wheel and tractor rear wheel to ensure the stability of vehicle.

3. When the trailer disengages the tractor, the brake line is cut off, or the trailer line is broken in an emergency, the trailer brake system will brake automatically to ensure safety. (note that this is not simply a parking brake.)

4. When the train is fully loaded, the tractor-trailer condition ensures safe and reliable parking on 16% of the ramp, and the trailer must be equipped with a parking brake system to ensure the braking condition when it is parked separately from the tractor

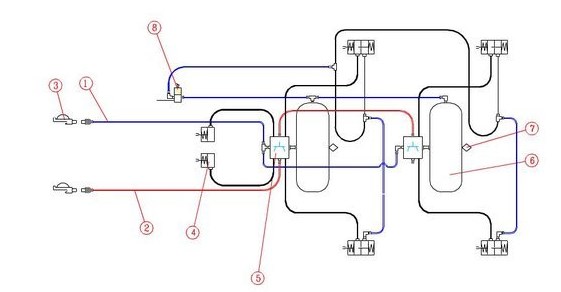

Diagram of semi-trailer brake air circuit arrangement

At present, the semi-trailer produced in China adopts the design of double pipelines. In the figure, 1 is the control pipeline, 2 is the control pipeline, which is connected to the tractor by 3 control air connections, here corresponds to the actual common vehicle gas supply pipeline for the red spiral tube, the control pipeline is generally yellow or blue spiral tube.

1. Gas Supply Pipeline

the tractor supplies gas to 6 gas storage cylinders through 2 gas supply pipelines, 5 emergency relay valves and 8 manual valves to the parking brake sub-pump (the parking chamber part of the parking brake sub-pump) . The parking brake is released when the air cylinder exceeds 4 bar.

2. Control line

when the brake pedal is pressed, 1 the control line passes through air, and 5 emergency relay valves are pushed open. At this time, 6 air storage tanks begin to supply air to 4 brake sub-pumps of each shaft, and the vehicle starts to brake, put the brakes on.